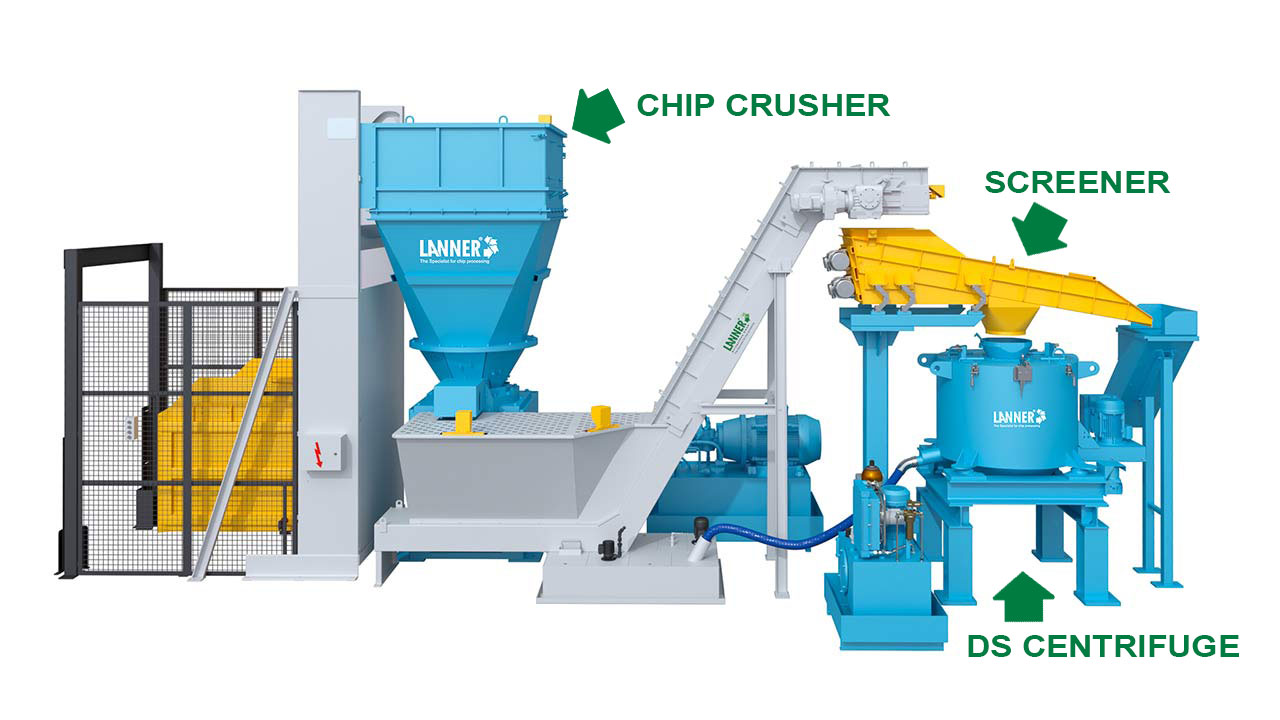

COMPLETE SYSTEM

All advantages at a glance

perfectly balanced components for max. throughput

much higher recyclability of the chips and the coolant

faster return on investment because of higher operating efficiency

on-site startup by Lanner engineers

smooth and fully automated operating

high operation reliability

Tailor-made complete solution

When fulfillment of customer requirements for chip processing meets highest throughputs and reliability, then it can only be an individual manufactured system from Lanner.

Using the newest technical standards our system can on the one side process up to ten tons of chips and on the other side it amortizes within shortest time. The systems from Lanner are treating the coolant containing chips in the best achievable way that they can be remolten up to nearly 100 % and without thermal drying. Besides that the regained coolant can also be reused almost completely and has not to be disposed expensively.

This is how a chip processing system works

A cart with chips containing coolant enter the chip processing system e. g. via fork lift or chip cart dumper. Depending on their shape chips have to be resized by a chip crusher. A conveyor transports the free-flowing chips to the centrifuge, if tramp metals are occurring a screener is necessary. The parabolic or lifting bottom centrifuge separates the coolant from the chips. These dry chips can be conveyed into e. g. a briquetting press, several containers or directly into a melting furnace. The separated coolant is collected in a tank and can be reused.

The entire system is controlled by a central control cabinet. Depending on the requirements concerning e. g. Industrie 4.0 the system can be expanded with additional components, such as automatic feeding via an automatic guided vehicle (AGV) or remote access.

How can we help you?