SCREENER

All advantages at a glance

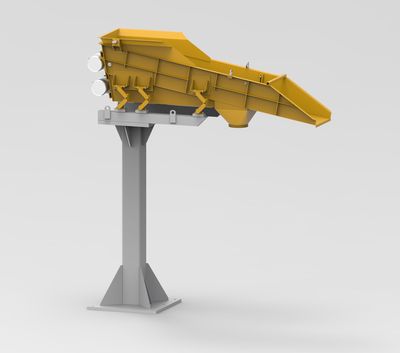

cascades and frame individually adjustable

several cascade executions available

perfect result of separation

adjustable unbalance drives

pivoting screener stand for maintenance

Separates the sheep from the goats

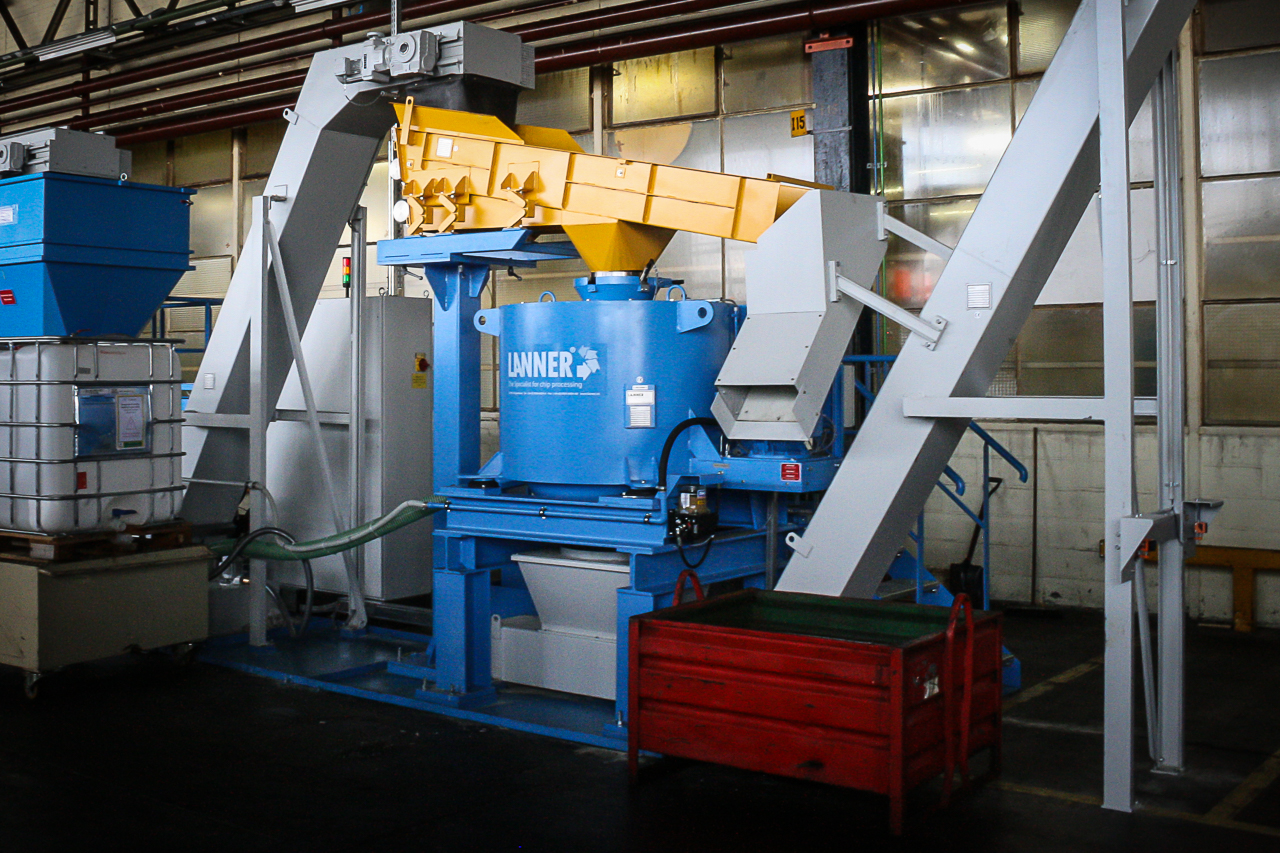

Fully automatic centrifuging or briquetting requires free-flowing chips without tramp metals. Your chips should be processed, but tramp metals like manufactured parts or broken tools cannot be avoided? No problem – using a screener from Lanner will reliably separate the tramp metals and the further processing will work out fine. The screeners from Lanner can be adjusted individually to fit to nearly every process – we really separate the sheep from the goats!

This is how a screener works

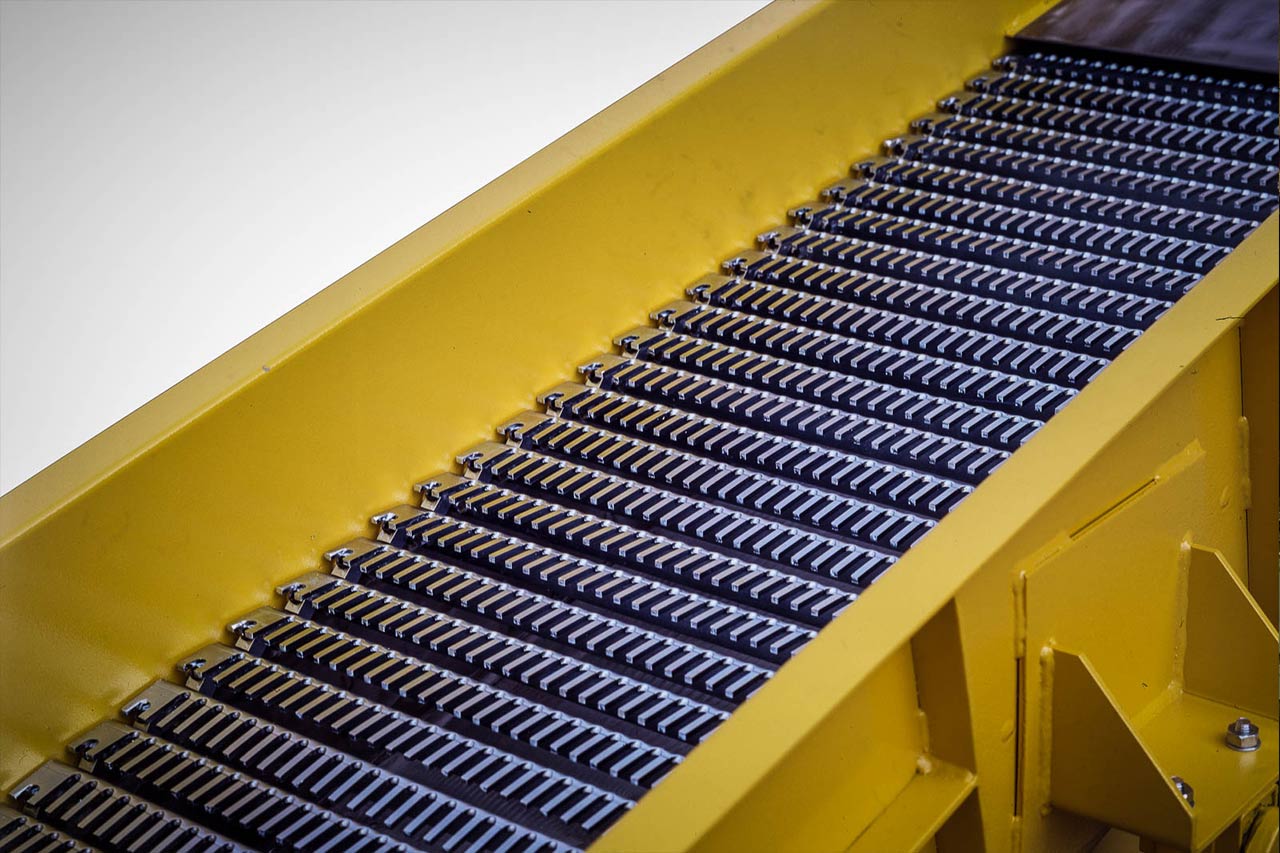

The material which should be processed is transported continuously e. g. via a steel belt conveyor onto a screen. The free-flowing chips are separated from the tramp metals and chip nests with vibration. The short chips fall through the sieve and can directly enter a parabolic centrifuge, lifting bottom centrifuge or briquetting press. The sorted out tramp metals and chip nests are collected in a cart.

How can we help you?